With time and new technological advancements, dentistry has experienced a giant leap. The recent inclusion of digital technologies like 3D imaging and printing in dental treatment is a boon to dental professionals and patients suffering from various dental problems.

3D printing technology has already revolutionised the design, engineering, defense, and aerospace industries. In recent years, it has greatly impacted the advanced dental solutions.

Let’s explore more about how 3D technology is bringing a new age to dentistry.

What is 3D Printing in Dentistry, and How Does It Work?

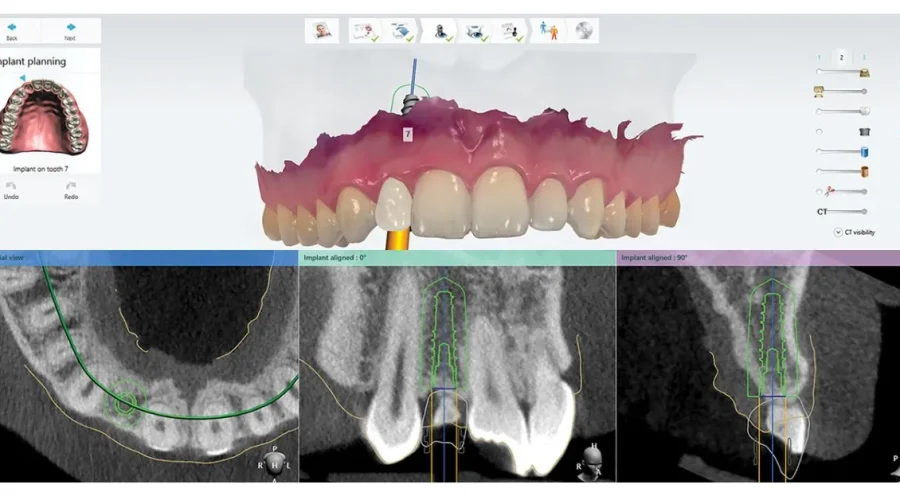

Dental 3D printing is the additional manufacturing process to create dental parts such as aligners, dentures, and crowns. To create custom parts that match a patient’s anatomy, dental providers use a tool called an intraoral scanner. This creates images of a patient’s teeth and records them in a CAD (computer-aided design) file. Dentists then use this CAD file to create implants or dental moulds through 3D printing.

In the past years, creating dental implants and moulds was cumbersome, invasive, and sometimes uncomfortable without using computer-aided design. 3D printing has significantly simplified and improved the work of treating dental patients.

Benefits of Advanced 3D Printing in Dentistry

Customisation:

3D printing allows precise customisation of dental implants, bridges, aligners, and crowns and helps the devices fit precisely into a patient’s mouth. This customisation process proved to be a better fit and aesthetic for patients.

Speedy Production:

While traditional methods take multiple days or weeks, the 3D printing process enables the rapid creation of dental appliances in a day or two, reducing the waiting period for patients.

Improves Accuracy:

Digital technology minimises human errors, ensures a higher level of accuracy in creating proper dental prosthetics, and reduces the need for adjustments or additional appointments.

Improves accessibility:

3D printing technology can extend quality oral health to areas where traditional access is limited for people. These advancements make it easy to address a wide spectrum of oral issues efficiently. Also, dental prosthetics made with 3D image printing are much higher quality products than conventional methods.

Cost Effective:

A 3D printer costs significantly less than a milling unit, and in-house 3D printing saves time and money. Also, 3D printing is more efficient and accurate than milling, particularly creating complex structures.

Applications of Dental 3D Printing

Custom Dental Modelling:

3D printing can be used to create custom tooth models. It also improvises visualisation and access to canal spaces, facilitating more accurate, effective treatment by offering a treatment planning and practice option for a case. Medical models can also be used in dental training and education, offering a safe and realistic way for learners to gain anatomical knowledge and practical experience.

Orthodontic Appliances:

Clear teeth aligners have gained popularity due to their discreteness and removability over fixed orthodontic appliances, like braces, to straighten crooked and gapped teeth. To fabricate the series of clear aligners, an intraoral scanner, virtual impressions, and 3D printing are used.

Crowns and Bridges:

Other orthodontic applications include bending wires or creating indirect bracket-bonding splints in multiple materials and crowns and bridges. 3D technology has been used for quite a long time.

Surgical Guides:

3D printing is increasingly used to create drilling and cutting guides, particularly in implant and maxillofacial procedures. CAD-generated 3D plans can be transferred to the operative site, allowing the precise placement required.

Dentures and Prosthetics:

Traditionally, skilled dental technicians created prostheses in a dental laboratory. Physical impressions were used, which were usually uncomfortable for the patient. Today, a virtual impression can be obtained easily using intraoral and extraoral scanners, based on which a prosthesis can be designed in CAD software. It is then printed with a 3D printer – all within the dental clinic.

Also Read: What is Guided Implant Surgery: Everything You Need to Know

The latest 3D printing technologies used in dentistry

Advanced Dental 3D printing makes use of all types of AM technology, including digital-light processing (DLP), selective laser melting (SLM), stereolithography (SLA), and selective laser sintering (SLS), that are used in modern-day digital dentistry. These technologies make life easier for dental service providers and deliver significant benefits to patients, such as customised and tailor-made prostheses, shorter treatment periods, precise solutions, less-invasive treatment plans, and less painful and affordable dental solutions.

Stereolithography (SLA):

One of the most widely used processes in dentistry, SLA is commonly employed for printing dental models, surgical guides, clear aligners, retainers, and temporary restorations such as crowns and bridges. Its high precision and ability to produce smooth surface finishes make it well-suited for intricate dental applications.

Digital Light Processing (DLP):

DLP is also used to print dental models, surgical guides, clear aligners, and temporary restorations. This process involves working layer by layer to build the 3D object. Its ability to cure an entire layer simultaneously makes it faster than SLA for certain applications. That’s why it’s an efficient choice for dental labs and clinics.

Selective Laser Sintering (SLS):

This technology employs a high-powered laser to selectively fuse and solidify powdered materials like metals, ceramics or polymers, layer by layer, creating 3D objects. SLS is primarily used to print metal dental implants, crowns, bridges, and other denture frameworks. It’s known for printing highly durable and strong biocompatible metals and ceramics.

Fused Deposition Modeling (FDM):

Rarely used in dentistry compared to other technologies, FDM can be used to print dental models, surgical guides, and temporary restorations using biocompatible materials like polymethyl methacrylate (PMM) or polyetheretherketone (PEEK).

The Future of 3D Printing in Dentistry

The possibilities with 3D printing in dentistry are endless and evolving over the years. Dentists all over the world are implementing 3D printing technologies in-house to increase treatment efficiency and overall accessibility and reduce treatment time. Although equipment, materials, and services differ from 3D printing technologies, there is still scope for further exploration for new and innovative applications in coming years.

With surplus dental companies and brands in an ever-competitive market, it is easily expected to have more and more new advancements in 3D technologies to cater to improved patient care, increasing efficiency, and time-saving methods continue to transform the field of digital dentistry.

FAQs

Yes, these materials are tested and proven safe, minimizing the risk of adverse reactions or complications for patients.

The treatment procedures may not be cheaper, but 3D printers can save money overall by reducing the number of materials needed for each procedure and the time it takes for the entire process.

3D printing in dentistry is mostly used as an additional manufacturing process to create highly efficient dental parts such as aligners, dentures, and crowns.